There are countless commercial biomass boilers in the United States that generate energy from various biomass sources, from softwood and hardwood to forest trimmings, grasses, paper waste, and agricultural byproducts.

To learn more about the products and maintenance services we offer for biomass boiler systems, contact our experts!

During the process of creating the growing amounts of energy these plants produce, these facilities also generate a tremendous amount of ash that must be handled. This is why each facility needs a dedicated ash handling system that can take care of the ash generated from plant production in a smooth, efficient, and cost-effective manner.

See our biomass boiler design guide here:

Here is a breakdown of the key components to a suitable ash handling system for a biomass to energy generating plant.

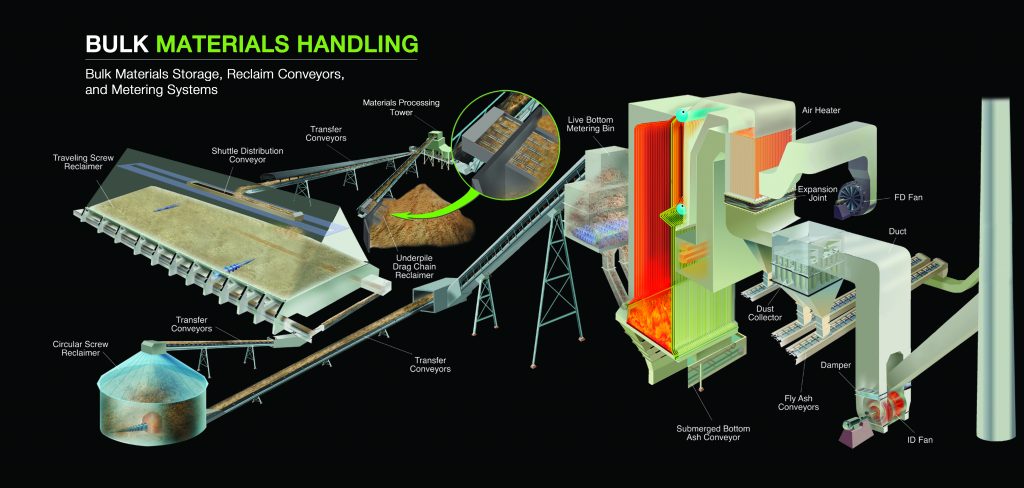

Fly Ash Conveyors and Bottom Ash Conveyors

The fly ash conveyor component is designed to transport ash residue to ash processing and storage components.

On your typical biomass boiler system arrangement, there are two general types of ash: bottom ash and fly ash. The first is designed to handle the residue that falls into the bottom hopper of the furnace. The second is designed to handle ash residue that escapes vertically from the furnace.

Our fly ash conveyors are built using a single-strand drag chain made from high-strength, drop-forged CrMn steel. They are engineered for air and dust-tight operation with abrasion-resistant materials for greater durability. They efficiently transport ash from back-end particulate collection devices such as the dust collector, precipitator, baghouse, etc. to the next components of the system.Bottom ash conveyors handle the solid ash particles, unburned biomass, and other solid constituents that come out of the furnace bottom area. They are sometimes called submerged bottom ash conveyors. Our bottom ash conveyors are built with a dual-strand drag chain made from high-strength/BHN welded steel. They are submerged with water to provide for air and dust-tight operation in biomass boiler systems.

Ash Conditioners

Once the fly ash has been transported to the fly ash silo via the silo inclined transfer conveyor, it must be unloaded. During this process, ash conditioners use water to moisten the dry ash to generate a substance that is damp and easily movable without entrainment back into the atmosphere. It is then transferred to a landfill for disposal.

Our ash conditioners use a three-stage process to gradually moisten the ash to help minimize the amount of water that is needed. The paddle screws are abrasion-resistant and made with ceramic tips for better longevity. They can process anywhere from 1,600 to 4,300 cubic feet of fly ash per hour.

Rotary Airlock Feeders

To help the boiler process run smoothly and efficiently by preventing outside air from entering the process – and to ensure environmental compliance – an ash handling process needs rotary airlock feeders or double dump valves.

These rotary airlock feeders are made from heavy-duty abrasion-resistant steels that are designed to be air-tight under reasonable pressures. They help to prevent the ash from building up in the biomass boiler system hoppers and keep tramp air from entering the process.

Double Dump Valves

Double dump valves are an alternative to a rotary airlock valve. Choosing the right type is more important.

Some plants use rotary valves, but these can eventually result in air leakage thanks to wear and tear. Double valves, on the other hand, do not. They allow for the smooth flow of material, but also prevent air and gas backflow. As such, they are highly useful as an alternative to a rotary valve.The double dump valves we construct come in three sizes, with three types for each size. The three types include Standard Temperature (for temps up to 650°F), High Temperature (for temps between 650°F and 1000°F and Wood Fired (for temps up to 650°F and materials that can withstand thermal shock).

Ash Storage Silos

The final component of a high-quality ash handling system is the ash storage silo.

Ash storage silos can be constructed for both fly ash and bottom ash applications. They range in size from 300 cubic feet to 17,500 cubic feet and are designed to work seamlessly with ash handling systems like the ones we have discussed.

Custom Services for Commercial Biomass Boiler Systems

When constructing ash storage silos, it’s important to find a contractor who can use materials and designs custom to your needs and your existing equipment.To learn more about what makes up a high-efficiency, high-performance ash handling system, contact our Ash Handling Division today.