Develop a process for daily, monthly, and annual maintenance and service on your industrial kiln fan to ensure reliable and efficient equipment operation. Read More

Develop a process for daily, monthly, and annual maintenance and service on your industrial kiln fan to ensure reliable and efficient equipment operation. Read More

Optimizing your industrial kiln fan increases production and improves efficiency. See how you can achieve maximum ROI by optimizing your ID kiln fan today. Read More

Focusing on the entire system allows our fan testing service to help drive efficiency and reach KPIs. Read More

Delaying equipment repairs in a manufacturing facility is dangerous. What are the risks of delaying industrial fan replacements, and what is the best course of action? Read More

See how our industrial fan experts can increase performance and extend the equipment life of underperforming fans for power generation, paper and pulp, and more. Read More

Efficiency is the name of the game for mechanical draft fans. An efficient fan is a productive one, and a productive fan is one that doesn’t increase costs and hurt a plant’s bottom line. There are several types of fan efficiency ratings. Not all are created equal. It helps to… Read More

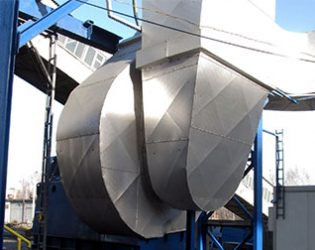

Plants use mechanical draft fans to move airborne material through a system duct and components. They are utilized to force, induce, and boost fluid media throughout the system – and use a large amount of power in the process. Mechanical draft fans operating at peak efficiency will show superior performance,… Read More

Ready to order your total systems solutions? Contact us for a quote.

Request a QuoteReach out to your local rep for more information.

Find Your Sales ContactIf you need immediate on-site equipment repair, contact us.

Call Emergency Repair