In this post, David Cantu, ProcessBarron’s Director of Materials Handling, shares his experience working with mechanical ash handling systems and pneumatic ash handling systems.

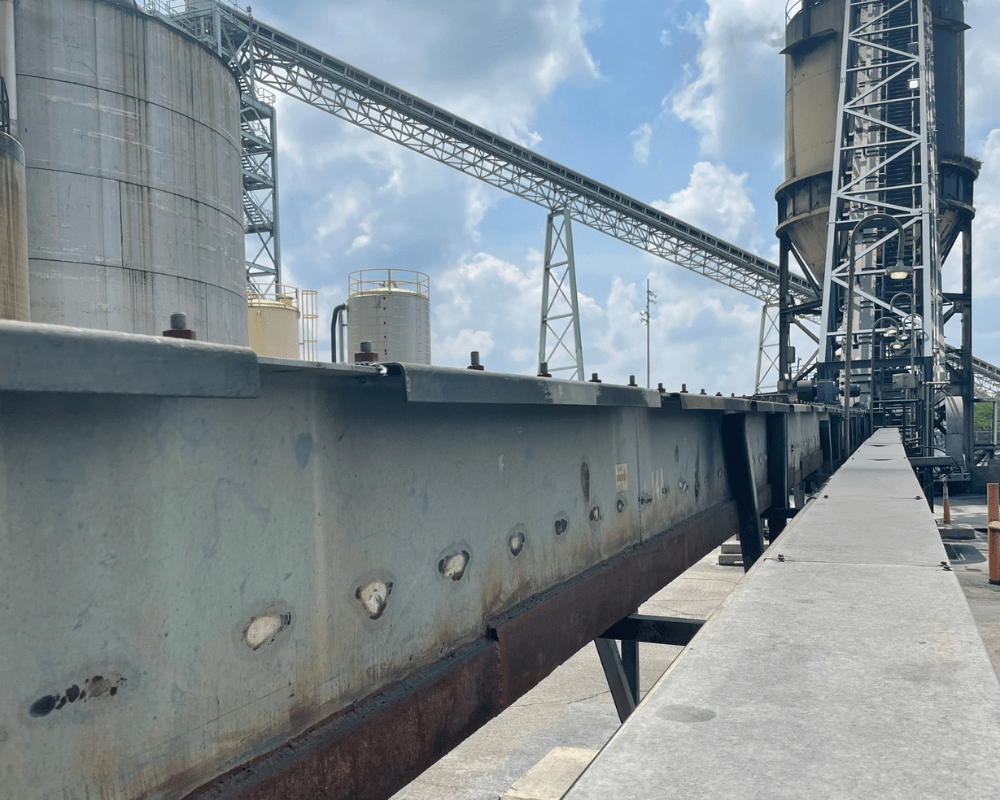

At ProcessBarron, we install mechanical fly ash conveyor systems. A lot of times, we are replacing older pneumatic ash handling systems. Each type of system has pros and cons, so I’d like to share our perspective.

Pneumatic fly ash systems have advantages. They often have a smaller footprint than mechanical fly ash conveyor systems, and they tend to be less expensive to install.

So with a lower up-front cost and a smaller footprint, why does ProcessBarron recommend mechanical conveyor systems?

Advantage 1: Mechanical Fly Ash Conveyors Continuously Evacuate Ash

Unlike the pneumatic systems that operate on a batch process, mechanical conveyors are always running to continuously evacuate the ash, keeping the hoppers empty. This can help if hoppers are prone to bridging.

Advantage 2: Mechanical Fly Ash Conveyors Use Less Energy

The blowers that drive pneumatic systems require more power. A pneumatic ash handling system might use a blower that requires more than 100 horsepower to move ash. Alternatively, you can run multiple conveyors with less than 20- horsepower. So swapping to a mechanical system can significantly reduce power consumption.

Advantage 3: Mechanical Fly Ash Conveyors Are Easier to Maintain

Pneumatic fly ash systems require a lot of maintenance. They have to blow ash through elbows and turns, and in systems with high ash loads, these multiple elbows tend to wear quickly and need frequent replacement. But, mechanical fly ash systems typically run at 10fpm or less, so you don’t have to replace components or sections often.

Advantage 4: Mechanical Fly Ash Conveyor Systems Are Safer

When you convey ash pneumatically, you introduce air to the ash, and unburned embers can reignite and cause a fire in the silo. This is one of the primary reasons many of our customers move away from pneumatic systems. With mechanical conveying, you don’t introduce any air. In fact, the system is airtight.

Because of the risk, a pneumatic system requires equipment on top of the silo to relieve pressure in the event of combustion. Pressure relief valves evacuate air to prevent explosions. This is necessary for safety, but it is another piece of equipment to maintain and another possible point of failure in the system.

Should I Replace My Pneumatic Ash Handling System?

If your safety protocols are in place, your pneumatic system may be fine for the time being. But if your facility is having trouble keeping ash contained or facing significant maintenance expenses, this might be the right time to consider a mechanical system. Contact us to find out what it would take to install a fly ash conveyor in your facility. We can further help by estimating maintenance costs of the new system and seeing how it compares to the cost of operating your current system.