Revolutionizing Industrial Fan Maintenance: Introducing SafeT Brake by ProcessBarron

Allen Ray, Vice President of ProcessBarron’s Air and Gas Handling Group, introduces SafeT Brake, a revolutionary rotor-locking device designed to transform industrial fan maintenance. This first-of-its-kind innovation is poised to minimize downtime and enhance safety in industrial parallel fan systems, addressing a persistent challenge that has plagued the industry for years.

The Challenge: Fans That Just Won’t Stop

Historically, the maintenance of industrial fans has consistently posed challenges of a complex and hazardous nature, especially in the context of fan clusters situated behind baghouses, electrostatic precipitators (ESPs), and analogous parallel fan systems. Various methodologies have been employed to halt the operation of fans resistant to slowing down, encompassing risky endeavors where frontline maintenance often used unsafe methods in an attempt to bring the fan to a stop. Notably, certain fans persist in spinning or even reversing their direction upon cessation, driven by residual air movement within the system, thereby posing a potential threat to the integrity of bearings and motors.

In response to these challenges, ProcessBarron has meticulously engineered the SafeT Brake, a game-changing solution designed from the ground up to address the unique needs of industrial fan maintenance with personnel safety and equipment protection being paramount.

SafeT Brake: The Safe and Efficient Solution

SafeT Brake emerges as a safe and reliable solution for stopping industrial fans and ensuring they stay stopped. The innovation lies in its interlock feature with the driving motor, allowing fan maintenance while other fans continue to operate. This groundbreaking feature opens the door to a more efficient and secure maintenance process, creating a safe situation for personnel, saving precious downtime, and protecting valuable equipment from damage.

One of the core functions of SafeT Brake revolves around locking the rotor to prevent free-spinning and disengaging the motor in reverse. This crucial design element significantly reduces damage to the bearings, couplings, and shaft, ensuring industrial fans’ longevity and optimal performance.

How SafeT Brake Works

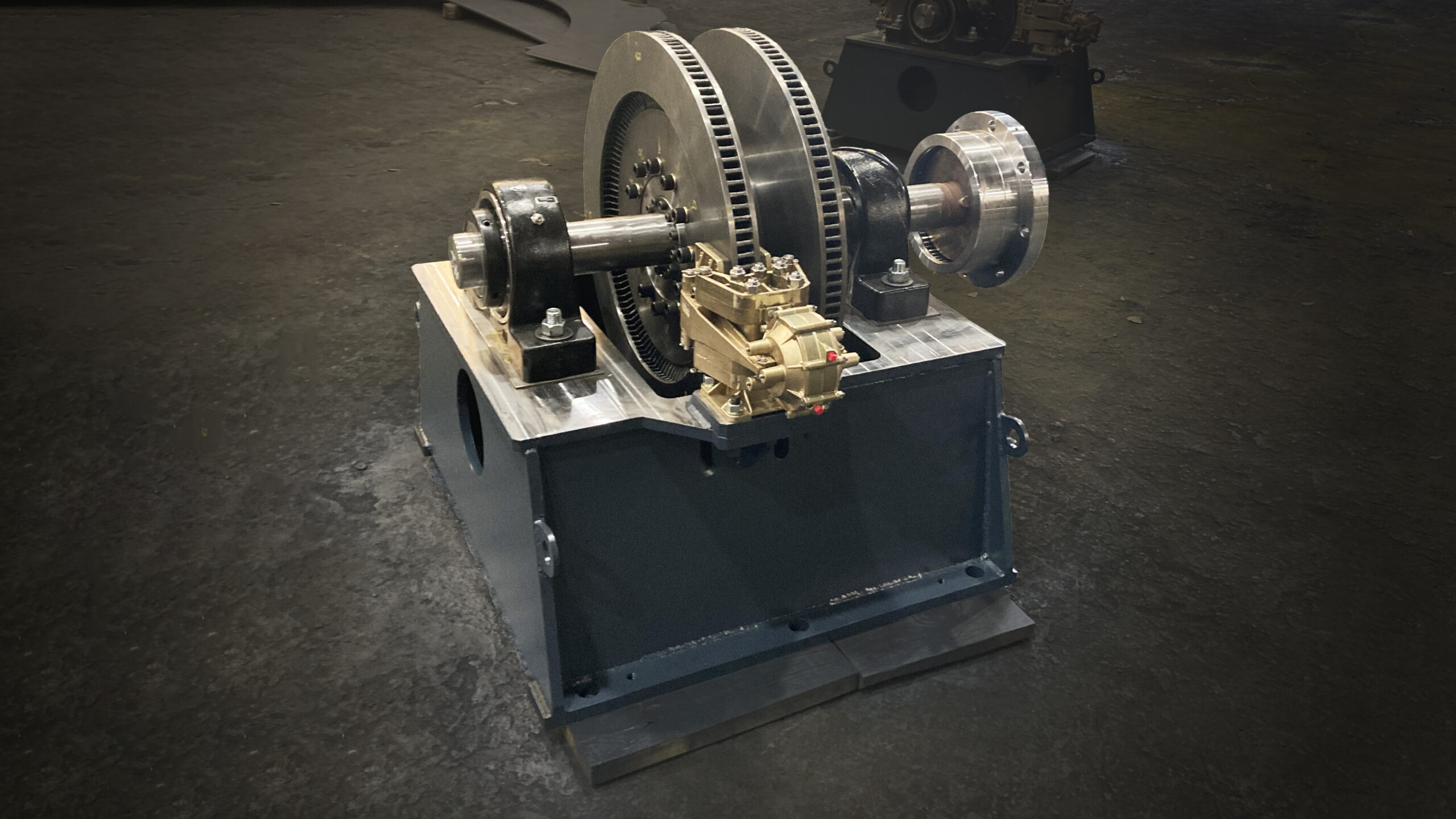

ProcessBarron’s SafeT Brake is a fully assembled brake system for industrial fans, boasting a range of features that set it apart in the market:

1. Dual-Disc Brake System for Dynamic Stopping and Holding

SafeT Brake incorporates a sophisticated dual-disc brake system, providing dynamic stopping and holding capabilities. This advanced design ensures precise control over the fan’s motion, allowing for a secure and efficient stoppage.

2. High-Energy Brake Discs with Air-Applied Brake Caliper on Each

The brake system features high-energy brake discs equipped with an air-applied brake caliper on each disc. This combination of advanced materials and pneumatic technology contributes to the swift and reliable operation of SafeT Brake.

3. 30-Second Stop Time from 900 RPM Using 50 PSI Air Pressure

Efficiency is at the forefront of SafeT Brake’s design, with an impressive 30-second stop time from 900 RPM using just 50 PSI air pressure. This rapid-stopping capability minimizes downtime and maximizes the productivity of fan maintenance procedures.

4. Control Package with Manual On/Off Push Button Switch and Integrated Safety Switch Brake Engagement

SafeT Brake comes complete with a comprehensive control package, featuring a manual On/Off push button switch. Additionally, an integrated motor-interlock switch ensures brake engagement only when the motor is de-energized, adding an extra layer of protection to the system. Also, the brake must be disengaged for a permissive start of the motor.

The Benefits of Using SafeT Brake

1. Safety

SafeT Brake stands as a positive locking device interlocked with the motor, enabling fan maintenance while other fans are still in operation. This pivotal safety feature enhances the overall security of maintenance procedures, mitigating potential risks.

2. Protection

By locking the rotor and preventing free-spinning, SafeT Brake significantly reduces the risk of damage to bearings, couplings, and the shaft. This protection ensures the longevity and reliability of industrial fan components.

3. Convenience

The elimination of long cost-down periods is a key advantage of SafeT Brake. The ability to bring the rotor to a full stop in less than a minute enhances the overall efficiency of fan maintenance, contributing to a more streamlined and productive industrial operation.

In conclusion, the introduction of SafeT Brake by ProcessBarron signifies a noteworthy advancement in the realm of industrial fan maintenance technology. This groundbreaking rotor-locking apparatus is more than just a remedy; it represents a transformative force for an industry contending with longstanding safety and efficiency obstacles. As we usher in this era of progress in industrial fan maintenance, SafeT Brake serves as a demonstration of ProcessBarron’s dedication to devising solutions that enhance safety, efficiency, and equipment safeguarding within the landscape of industrial manufacturing. Reach out to ProcessBarron today to delve into how SafeT Brake can redefine and optimize your industrial fan maintenance procedures.