When it comes to high-temperature, high-movement industrial systems, expansion joints may not always be top-of-mind, but they should be. These components are often small and overlooked, but their role in preventing costly system failures, unnecessary downtime, and long-term maintenance issues is critical.

In this blog, we go beyond the basics, pulling insights from our seasoned product manager, Nathan Rice at ProcessBarron, who’s been in the shop, field, and the drafting room. We’ll break down the key types of expansion joints, what to consider when selecting one, red flags to watch for, and real-world examples of costly mistakes and big wins.

Why Expansion Joints Matter

Expansion joints are engineered to absorb movement, temperature fluctuation, vibration, and misalignment in industrial duct systems. They prevent cracking, leaks, and mechanical stress in high-load environments. Yet, many procurement teams and plant managers still treat them as an afterthought, often waiting until the last minute to order replacements. This can lead to unplanned outages, rush charges, and system failure.

“I wish more plant teams understood the importance of routine inspections, because when joints fail, it’s usually preventable,” explained Rice.”

Expansion Joint Applications in Industrial Environments

From pulp and paper to cement, power, or waste incineration, it comes with specific temperature, media, and movement requirements.

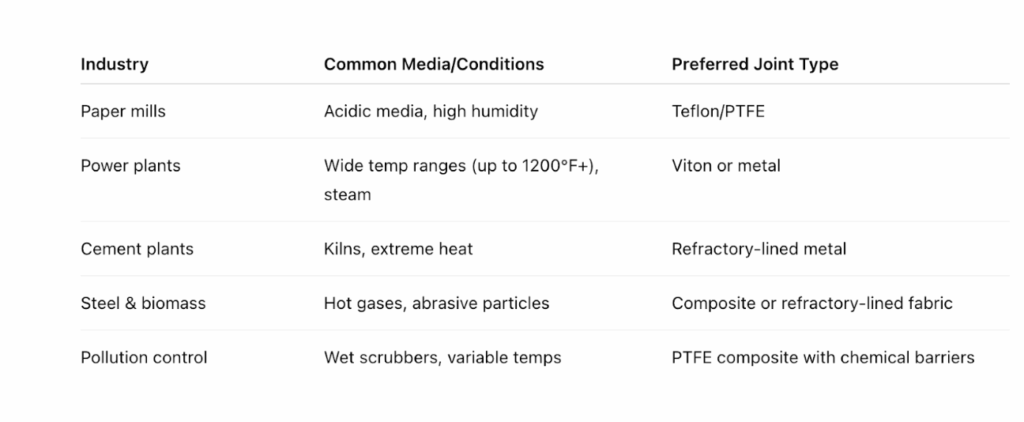

Here are a few examples of how expansion joints vary by application:

Whether you’re installing a fabric joint or upgrading to a metal bellow, temperature, pressure, flow media, and available space all influence the design.

Understanding the Lifespan: Fabric vs. Metal Expansion Joints

Fabric expansion joints typically last a year and a half to 2 years, depending on temperature, exposure, and movement. Metal expansion joints, under favorable conditions, can last 5 to 7 years or longer.

“I’ve replaced metal joints that have been in place since the 1970s. If they’re not seeing a lot of movement or temperature spikes, they can last decades,” said Rice.

However, longevity depends heavily on correct application, maintenance, and regular inspections.

Common Causes of Equipment Failure and How to Prevent It

Too often, expansion joints fail due to improper selection or delayed maintenance. Here are red flags to look for during inspections:

- Color changes on Teflon covers (whitening or softening) = hot spots.

- Cracking or dry rot on rubber/Viton joints = UV damage or aging.

- Burned fabric or exposed insulation = internal degradation.

- Airflow leaks = tears, holes, or seal failure.

“The joint will tell on itself. If it looks different from the rest of the system, it’s probably time to replace it,” explained Rice.

Proactive inspections, especially during outages, allow for replacements on your schedule, avoiding emergency installs and inflated costs.

Save Time and Money with the Right Expansion Joint

A large industrial facility had a recurring and expensive issue: its kiln expansion joints were blowing out twice a year. Each failure led to emergency maintenance, system downtime, and the cost of replacing the same poorly selected product over and over.

“They kept replacing it with the wrong selection. It wasn’t the customer’s fault; it just wasn’t the right joint for the application,” said Rice.

Recognizing that a simple replacement wasn’t going to fix the root cause, our team initiated a deep technical review. This included months of collaboration between ProcessBarron engineers and the customer’s internal engineering team to evaluate:

- Design restrictions (like the need for fiberglass-free materials)

- Performance expectations

- Material limitations

- Installation constraints

“They couldn’t accept fiberglass in their system, so that ruled out some options. We had to dig deep into design criteria and past failures to figure out what would actually work long-term,” explained Rice.

After weeks of back-and-forth analysis, meetings, and technical refinement, a new joint design was finalized and installed across eight points in the system.

The Result?

- The joints have now been in service for over 18 months without failure

- The customer avoided two full replacement cycles, saving substantial material and labor costs

- The downtime risk was significantly reduced, increasing system reliability and uptime

- There was no need to send engineers onsite, saving time and resources for both teams

“This expansion joint solution has already paid for itself. They were buying twice a year, and now they haven’t had to replace those joints at all. That’s a huge win for our customer,” said Rice.

The power of collaborative engineering and the value of investing upfront in the right solution, not just a fast one, are the key takeaways in ensuring you aren’t solving the wrong problem. We are committed to problem-solving, not just product-selling.

The Importance of Planning and Inspections

Even with top-tier engineering, high-performance materials, and experienced crews, last-minute expansion joint replacements are still incredibly common in industrial settings. But why is that the case?

“More than 70% of the expansion joint orders we receive are last-minute, with less than two weeks of lead time. To me, that’s a clear sign that regular inspections aren’t being prioritized,” stated Rice.

In many cases, inspections aren’t being done until a plant is already mid-outage, often after crews have focused on larger equipment like fans, kilns, or ducting. That’s when someone finally notices a failing expansion joint, turning what could have been a simple, planned replacement into an expensive, reactive fix.

Skipping inspections leads to:

- Emergency labor costs to mobilize crews on short notice

- Rush freight charges to get parts onsite ASAP

- Production delays due to unplanned or extended outages

- Compromised safety when failing joints go unnoticed until it’s too late

Visual indicators often reveal problems before failure.

Look for:

- Cracking or dry rot on rubber or Viton joints

- Discoloration or whitening on composite joints (a sign of hotspots)

- Fraying or exposed fabric

- Noticeable airflow or leakage from the joint itself

The smarter approach?

Plan proactively and replace joints during scheduled outages when the cost and risk are much lower. ProcessBarron excels at fast turnarounds for rush jobs and discoverable failures. Our goal is to help customers avoid those situations altogether through better planning and education.

Why Customers Trust ProcessBarron

ProcessBarron has built a reputation on more than just product quality; it’s about responsiveness, problem-solving, and a commitment to doing what’s right for the customer.

“We’ve got engineers who can work through any frame type. Even if you didn’t know there was a problem, we’re here to help you solve it fast,” said Rice. That kind of agility matters, especially when unexpected issues arise during outages or routine maintenance. ProcessBarron is equipped to handle rush jobs, discoverables, and unusual design constraints, quickly and accurately.

A key part of ProcessBarron’s reliability comes from our adherence to the industry’s most respected technical resources:

- FSA (Fluid Sealing Association) for fabric joint standards

- EJMA (Expansion Joint Manufacturers Association) for metal joint specifications

With an experienced engineering team, we can customize and adapt solutions when off-the-shelf or rigid specs won’t cut it. That’s why customers continue to trust us, not just for what we build, but how we think. Need help with your expansion joints or other equipment needs? Contact us today to get a quote!

ProcessBarron handles everything better. Find a ProcessBarron sales representative today!