More often than not, draft systems and industrial fans are not operating at their peak efficiency. Given today’s competitive climate, evaluating the operation of these fans and systems to adjust capacity and examining ways to improve efficiencies is a smart business decision.

- Simple steps, big savings. Often, engineers overlook the energy drain that can occur in the duct work, expansion joints and fan systems. Addressing these areas can result in major cost savings.

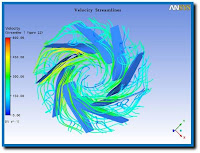

- Hunting down the leaks. Draft System Assessments test existing equipment and utilize computational fluid dynamics (CFD) to identify leaks and points of inefficiency.

Draft System Assessment CFD - From top to bottom. Temperature, abrasion, corrosion, stresses and harmonics are evaluated to come up with the most efficient, economical and productive design for each piece of equipment to reduce power requirements and increase capacity and cost savings.

- Identifying the culprit. Industrial fans are some of the largest parasitic loads required in the operation of a boiler. Draft System Assessments will identify changes that can improve fan efficiency. (ID fans, FD fans, over-fire air fans, flue gas-recirculation fan, etc.)

- The numbers add up. Repairing leaks, replacing faulty draft system equipment; or identifying unnecessary losses from poorly designed changes in cross-section areas, elbows, transitions to equipment, etc.; can add up to significant savings. These savings, along with ROI and CO2 reductions, can be calculated from an assessment.

Learn more about a how a draft system assessment from Process Barron can help your facility generate huge energy savings.