Over the past 10 years, renewable energy has become the fastest-growing energy source in the United States. Companies worldwide, including those in industrial manufacturing, are taking steps toward global decarbonization through increased use of renewable energy resources.

The primary sources of renewable energy are:

- Water

- Wind

- Solar

- Geothermal

- Biomass

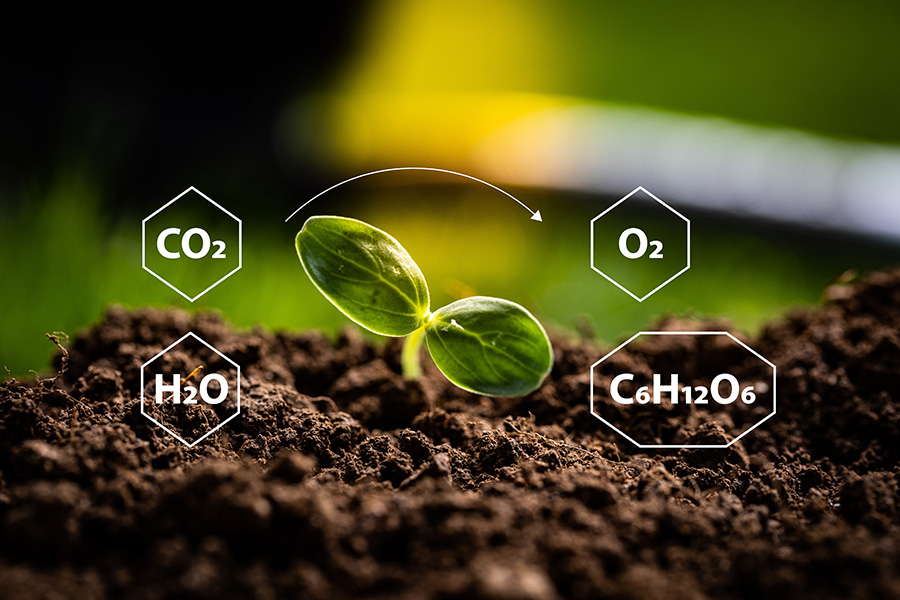

The industrial manufacturing sector derives most of its renewable energy from bioenergy, a form of renewable energy produced from biomass. Biomass is derived from plant and animal resources and can be used to create heat, electricity, fuels, and products for renewable energy. Biomass provides a cost-efficient way for plants to increase their use of renewable energy and reduce their carbon footprint.

Types of Renewable Bioenergy Resources

There are 4 major types of biomass energy sources:

Wood and Wood Waste

Wood and wood waste comprise bark, trimmings, chips, and sawdust. Wood waste supplies approximately 44% of biomass energy. Wood waste is used to generate electricity via combustion. Paper mills and power plants commonly use wood waste to fuel their boilers. Paper and saw mills are considered cogeneration plants because they create wood waste used to generate steam and electricity. In addition to wood waste, pulp and paper mills create a by-product called black liquor during the pulping process. The black liquor is used as fuel in a recovery furnace or boiler.

Wood and wood waste products need well-designed fuel feed systems to gather, sort, and convey the materials with precision. Is your fuel feed system effective?

Agricultural Crops & Waste

Agricultural waste, such as fruit pits and corn cobs, is also used to create solid biomass fuel. In addition, crops such as corn and soybeans are used to create biofuels.

Bagasse is a common biomass fuel that comes from the residual remaining from sugar cane stalks in sugar production. Like wood waste, bagasse produces steam and electricity through combustion. A bagasse cogeneration plant needs to pay special attention to creating the optimal airflow to the boiler or furnace.

Biofuels are primarily used as transportation fuels. They also have some applications in heating and electricity generation. They are broken into 4 main categories:

- Ethanol

- Biodiesel

- Green diesel

- Other biofuels

Municipal Solid Waste

Other companies burn municipal solid waste (MSW) (also known as garbage) composed of paper, yard waste, food, wood waste, and other ingredients. MSW is not all biomass, as it will also contain plastics not derived from natural resources.

Most MSW in North America is used in waste-to-energy plants. It is used to produce steam in a boiler for electricity generation or to heat buildings.

The most common MSW combustion method is a mass-burn system, which can be extremely corrosive to your equipment. There are often batteries, paint, and other items that are supposed to be disposed of in other ways but still get mixed into the trash these plants are burning. Flue gas toxicity is higher in these plants, which places more load on the APC equipment. Proper operation and maintenance of baghouses and precipitators are vital for these facilities.

If, during this process, your precipitator drops below 225 degrees, it starts creating sulfuric acid and some other emissions that can damage your equipment.

Here are our top 3 strategies for maintaining your ESP.

Biogas

Biogas is a result of the anaerobic decomposition or thermochemical conversion of biomass. Biogas is composed mostly of methane and carbon dioxide but can be treated to remove the carbon or burned directly as a fuel.

Not only is biogas a renewable and eco-friendly energy source, but it is also often used by municipalities in their water treatment facilities. Biogas produced by the facility’s anaerobic digester creates heat that enhances the digestion process and kills or reduces pathogens in the water.

Using biogas instead of natural gas is extremely cost-effective and has the added advantage of its residual product, degassed biomass, which is used for fertilizer.

Conclusion

Where fossil fuels are limited, biomass sources are made from natural, reoccurring resources the planet is constantly generating. The renewable energy trend is here to stay.

Many of our customers are driving the efforts in their sector to incorporate different types of renewable energy into their production processes. Transitioning from fossil fuels to renewable fuel sources is a large investment. During this transition, ProcessBarron is actively partnering with facilities to design new systems, manufacture and install equipment, test and inspect systems for efficiency, and maintain production output.

ProcessBarron is committed to “clean and efficient manufacturing” and helping plants across the US and Canada reduce their carbon footprint and increase energy efficiency.