PRODUCTIVITY

EFFICIENCY

OPPORTUNITIES

ProcessBarron and SouthernField EEC have combined their prospective expertise and developed an innovative approach to combating the efficiency issues that prohibit optimal production levels. Our industrial efficiency program is built around four pillars: safety for your employees, maximizing productivity during your annual outage season, increasing plant efficiency in daily operations, and discovering profit opportunities for your business.

Reserve an IEP appointment here to learn more about our innovative, total-system approach to reduce carbon emissions and energy costs for your plant.

Improving Efficiency in Industrial Systems

Our Industrial Efficiency Program uses cutting-edge technology to provide a multi-faceted examination of your industrial systems.

Our IEP technicians have 40+ years of experience exploring industrial manufacturing production systems to identify ways to create energy savings and reduce emissions through optimal system performance.

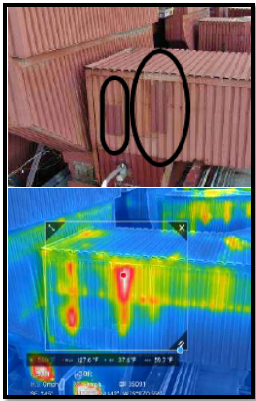

ProcessBarron and SouthernField’s IEP leads the industry through its one-of-a-kind comprehensive internal inspection and external visual and thermal analysis of your system. See the video and graphics below for a visual example of our thermal analysis capabilities using drone technology.

Total System Approach

Maximizing Industrial Efficiency using an Innovative, Total-System Approach

In the last decade, forward-thinking organizations have recognized the benefits of setting goals to reduce greenhouse gas (GHG) emissions, including discovering opportunities to reduce expenses, encouraging innovation, and setting new standards for how corporations relate to the environment.

We understand the importance of these corporate goals, and our team of experts has the tools and resources to help you reduce your carbon emissions and plant energy costs.

See some examples of how our industrial energy efficiency program impacted plants across several industries! See the industries we serve here.

Industrial Efficiency Case Studies:

Cement Plant

Scope of Services: Inspect underperforming ID fan

Testing Conclusion: Excessive amount of air in-leakage

Estimated Savings: $354,760 / yr in energy savings with suggested improvements to optimized system

Steel Plant

Scope of Services: Inspect baghouse ID fans & system to pinpoint issues causing repetitive repairs

Testing Conclusions: (1) Fans operating above max amp load (2) Inlet dampers opening at 20% and (3) 20% operational efficiency

Estimated Savings: $472,795/yr (Energy & Maintenance Savings) AND

7,729 metric tons/yr Reduced CO2 Emissions

Power Plant

Scope of Services: Aerial and thermal inspection of baghouses, dry scrubbers, and surrounding ductwork to identify possible air pollution control issues

Inspection Conclusions: Discovered needed repair areas showing very high temperature deviations (indicating thinning of steel, corrosion, holes and/or cracks) which should be focus of pre-planning for future outage.

Estimated Savings: $20,000/ day in outage savings due to more efficient pre-planning maintenance service in hard-to reach areas

Average Total Savings: $100,000 – $250,000 per outage

Paper Plant

Scope of Services: Thermal inspection of recovery boiler, electrostatic precipitator inlets, outlet plenums, and ductwork for heat signatures indicating heat loss.

Inspection Conclusions: (1) Immediate action needed to repair damaged areas that are potential compliance issues. (2) Precision outage planning focused on parts and service to address six specific problematic areas discovered during testing.

Immediate Savings: $10,000 – $60,000/violation (Potential fines)

Outage Savings: $300,000 – $450,000 by avoiding rebuild and saving on scaffolding expenses

Contact us here to learn more about how we can support you through efficiency improvements, cost savings reduced emissions.